What is the difference between a vertical lathe and a regular lathe |

| Time: 2021-01-28 View: 3553 Burst: |

|

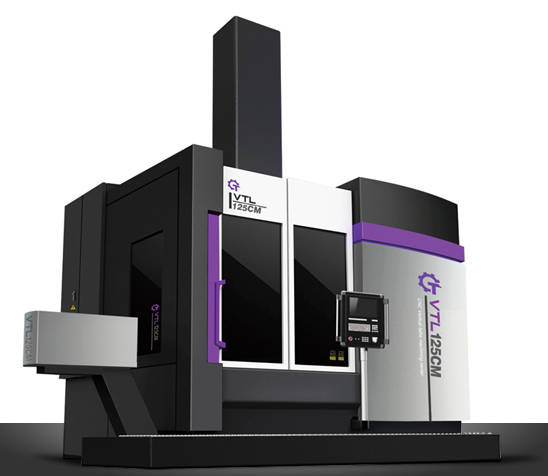

Vertical lathe and CNC vertical lathe, I believe many people know about them, but what are the differences between them? Are they the same as ordinary lathes? Let's analyze them briefly below!

Ordinary lathes rely on gears and ordinary screw nuts for transmission. Due to gaps between the various motion pairs and incorrect manual manipulation, the repeatability accuracy is relatively low. When measuring with a regular lathe, it is necessary to manually measure after parking, which results in significant measurement errors and low efficiency. Suitable for small batch sizes, low precision requirements, and miscellaneous parts. It has lower investment compared to CNC, but requires higher skills from workers, resulting in higher wage levels. The waste source rate and production rate of low-level workers will give you a headache. Vertical lathes are mainly used for large components, and their spindle is vertical. Vertical cars also have CNC technology. Due to the increasing shortage of high-tech talents, new enterprises are now adopting CNC technology to improve production rates and product quality, reduce scrap rates and costs. Its main axis is perpendicular to the ground. The difference between it and regular car orders is that it has a larger diameter for processing. In this case, the smallest vertical ordinary lathe in our country can process workpieces with a diameter of one meter. |