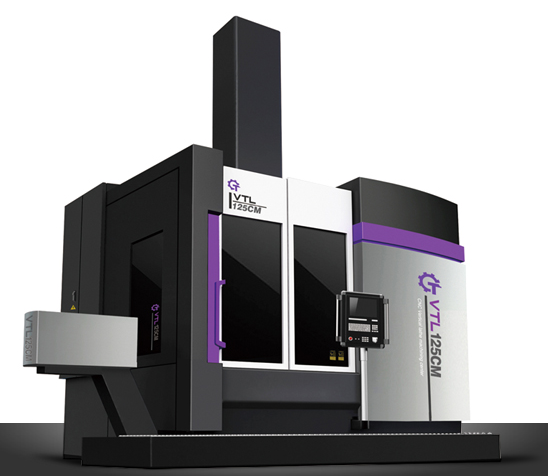

Must see! The process of CNC vertical lathe machining |

| Time: 2021-01-19 View: 2751 Burst: |

|

What is the difference between CNC vertical lathe and automatic lathe? At first, we need to understand the machining principles of automatic lathes and CNC lathes. Automatic lathes use cam movements to drive the cutting of knives, while CNC lathes use programming to control the movement of knives. In terms of power, automatic lathes are much higher than CNC lathes, so the machining cost of automatic lathes is cheaper than that of CNC lathes. If the product is more complex and has higher requirements, automatic lathes may not be able to do it, so only CNC lathes can be used. However, its machining cost is higher than that of automatic lathes. For a product, whether we choose to use automatic lathes or CNC machining depends on the difficulty of the product.

The process of CNC vertical lathe machining is similar to that of general lathes, but because CNC lathes are one-time clamping and continuous active machining to complete the turning process, attention should be paid to the following aspects and the cutting parameters should be selected reasonably: for high-power metal cutting machining, the material to be machined, the cutting object, and the cutting premise are the three major elements that determine the machining time, tool life, and machining quality. The economically effective machining method is to select the cutting premise reasonably. The three elements of cutting premise: cutting speed, feed rate, and cutting depth directly cause damage to the tool. With the increase of cutting speed, the temperature of the tool tip will rise, which will cause mechanical, chemical, and thermal wear. A 20% increase in cutting speed will reduce the tool life by half. The premise of feed and the wear behind the tool occur within a small range, but with a large feed rate, the cutting temperature rises, and the wear behind the tool is greater. It has less impact on the tool than cutting speed. Although the effect of cutting depth on the tool is not as large as cutting speed and feed rate, in small depth cutting, the material being cut will form a hardened layer, which will also affect the tool life. Users need to select the cutting speed to be used based on the processed data, hardness, cutting condition, data variety, feed rate, cutting depth, etc. The selection of suitable machining prerequisites for CNC vertical lathes is based on these factors. Choosing a CNC vertical lathe processing plant with regular and stable wear to reach the desired lifespan is the ideal prerequisite. However, in practical work, the selection of tool lifespan is related to tool wear, changes in processing standards, surface quality, cutting noise, processing heat, etc. When it comes to machining prerequisites, research needs to be conducted based on actual situations. For difficult to machine materials such as stainless steel and heat-resistant alloys, coolant or rigid cutting edges can be selected. Turning is the use of workpieces on CNC lathes. The method of cutting workpieces by rotation, The cutting energy of turning machining is mainly supplied by the workpiece rather than the cutting tool. Turning is a basic and common cutting method, and it is suitable for machining reverse surfaces. Most workpieces with reverse surfaces can be machined using turning methods, such as cylindrical surfaces, conical surfaces, end surfaces, grooves, threads, and reverse forming surfaces. The main tool used is a turning tool. |