What are the uses of vertical lathes |

| Time: 2021-01-20 View: 2130 Burst: |

|

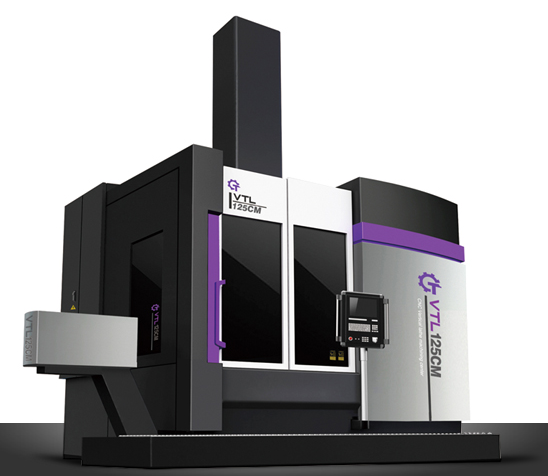

A vertical lathe is used to machine workpieces with relatively large diameters and weights, or workpieces that are difficult to install on a horizontal lathe. The spindle axis is perpendicular to the horizontal plane, and the workpiece is installed on a horizontal rotary worktable. The worktable has the main motion of rotating motion, and the vertical and side tool holders achieve feed motion.

Vertical CNC lathes are also used for processing large and heavy workpieces with large radial dimensions and relatively small axial dimensions, and complex shapes. Such as cylindrical surfaces, end surfaces, conical surfaces, cylindrical holes, conical holes, etc. of various disks, wheels, and sleeve workpieces. Additional devices can also be used for machining threads, spherical surfaces, profiling, milling, and grinding. Compared with horizontal lathes, workpieces are clamped inside the clamping decoration of horizontal lathes. The spindle axis of the vertical CNC lathe is arranged vertically, and the worktable is in a horizontal plane, so the clamping and alignment of the workpiece are relatively convenient. This layout reduces the load on the spindle and bearings, so the vertical CNC lathe can maintain working accuracy for a longer period of time. Vertical lathes are large mechanical equipment used for processing large and heavy workpieces with complex shapes, with large radial dimensions and relatively small axial dimensions. Such as cylindrical surfaces, end surfaces, conical surfaces, cylindrical holes, conical holes, etc. of various disks, wheels, and sleeve workpieces. Additional devices can also be used for machining threads, spherical surfaces, profiling, milling, and grinding. |